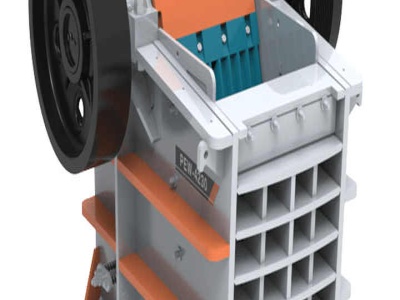

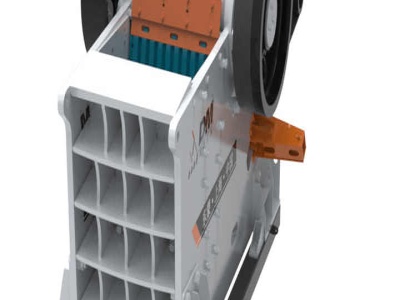

Jaw Crushers

Rocksizer Jaw Crushers. RockSizer primary stage jaw crushers feature the upthrust toggle action which is also common to the StoneSizer range. Developed by Parker, this gives a slight downward movement to the swing jaw that promotes a forced feed and therefore increased output while at the same time minimising any rubbing action resulting in a well shaped product and reduced and even wear on ...