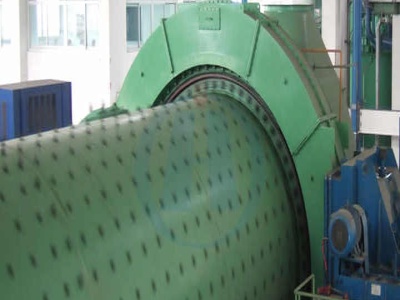

npk crusher | Fine pulverizer for sale

What fertilizer powder pulverizing equipment is applicable for your high output fertilizer production requirements? These 3 types of grinders are high output equipment. It is suitable to use them for your large scale fertilizer production line. Their output can reach 20 ton per hour. And with these machines, you can get well pulverized fine powder.